Home / Our Products / Full-Automatic Low Voltage Wire Harness Manufacturing Machine

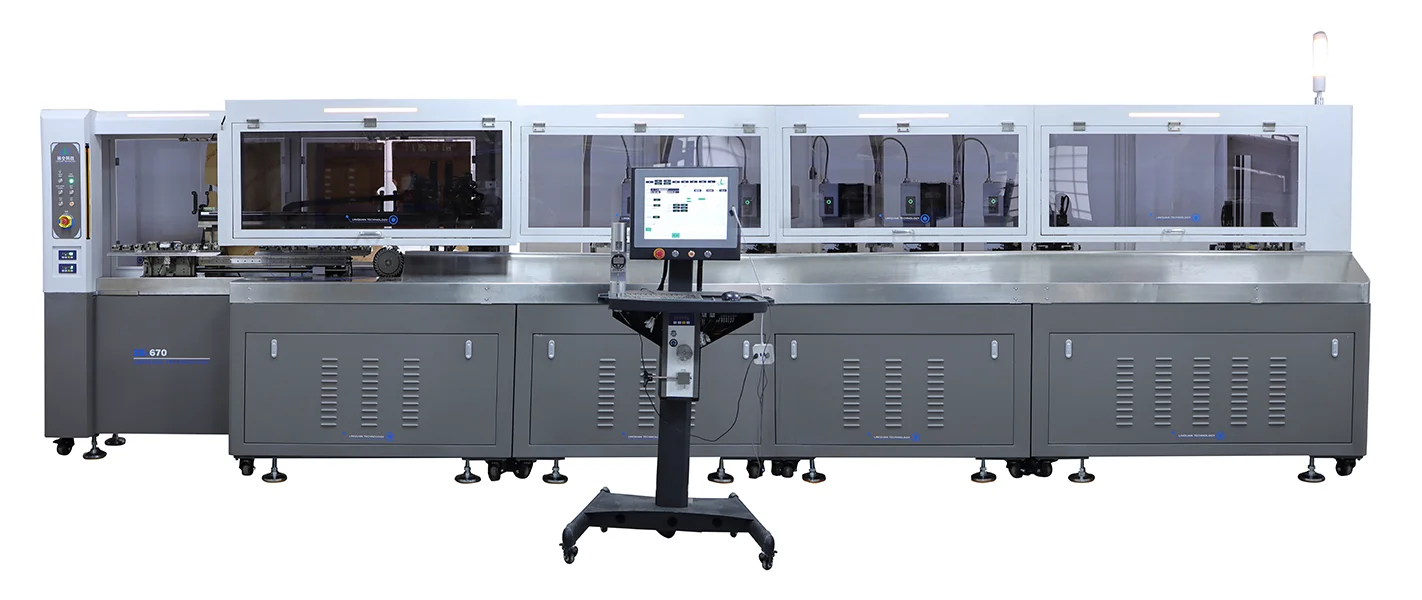

Full-Automatic Low Voltage Wire Harness Manufacturing Machine

ZE-680

Equipment Configuration

- With the German high pixel CCD inspection system

- Module (THK), Electric engine (YASKAWA), Pneumatic mould (SMC), Sensor (Omron), CCD Camera (Basler), Reducer (Nidec-Shimpo), PLC (Keyence), Servo drive (Mitsubishi)

- The maximum productivity can reach to 1200pcs/hr

Equipment Function

- Wire selector up to 50 different specifications and colors of wires

- CCD visual inspection, CFM (Crimping Force Monitoring), Insertion/Pull-back force detection

- Both-end terminal stripping, Sigle-end housing Insertion

- Simultaneous multiple housing insertion

Technical Parameters

| Efficiency: | Both-end crimping, single-end insertion, about 1200pcs/hr (Depends on different producing process and the functional module quantity, productivity is different) |

| Drive Mode: | PLC |

| Wire Size: | 0.13mm²——2.0mm² (AWG 26-14) |

| Mould Assembly Type: | AS40、AS42、AE30(pneumatic mould can be customized) |

| Cutting Length | 270-9999mm |

| Cutting Precision: | Cutting length<100mm, Error Range ±0.5mm + (Setup cutting length*0.002), Cutting length>100mm, Error Range ±1mm + (Setup cutting length*0.002) |

| Stripping Length: | Both sides(crimping ends)0-15mm |

| Penetraction Depth: | Maximum 3mm |

| Crimping Capacity: | 2TON Servo motor five sets mute specifications |

| Power Source: | 3 phase 380V/50Hz |

| Power: | 13KW |

| Compressed Air Connection: | 0.5Map |

| Equipment Size: | L5050*W3000*H1900mm |

| Weight: | Ahout1500KG |

| Detection Device: | Wire presence, Wire overload, Terminal presence, Terminal overload, Stripping and crimping visual monitoring, Crimping force monitoring, Housing presence, Insertion error detection, Liquid tin level detection |

| Function: | Pre-feeding, Wire feeding, Fixed length cutting, stripping, single end twisting & tinning, single-end crimping, single-end insertion, adjusting crimp height on HMI, unloading defective products through CCD inspection |

| Optional: | Lin Quan MES System, Laser Inkjet Print, Seal insertion (Max 6 modules)Tinning & Twisting, Wire Stranding, Wire end solidifying, splicing, welding, Double crimping, Max.12 Crimping Modules (with programmable crimp height) |

Request your quote now!

Share your information with us and we will contact you as soon as possible.

LOOK AT OTHER PRODUCTS

-

-

-

-

-

-

Automatic Seal Feeding Machine

-

-

-

-

-

-